Automotive Supply Chain Insights: Fastener Coating Selection for EV Chassis: Key Considerations and Practical Guide

Dear Engineers and Procurement Professionals,

Are you navigating the complexities of selecting the right fastener coatings for critical components in Electric Vehicle (EV) chassis? As the core structure of an EV, the reliability of its fasteners is paramount. Beyond their primary function of joining parts, these fasteners must withstand challenging environments, resist corrosion, control friction, and ensure long-term safety.

This newsletter focuses on the coating selection for fasteners in EV chassis, providing you with key considerations and practical recommendations to facilitate more informed decisions.

Coating Selection Considerations for Key Components:

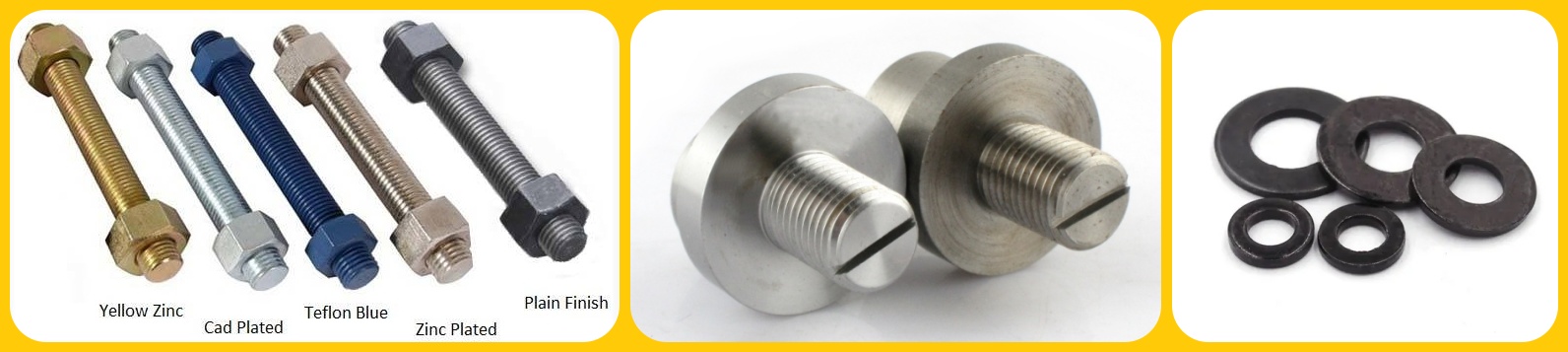

Battery Pack Fasteners: Environmental Characteristics: Potential contact with battery electrolytes, requiring high chemical corrosion resistance. Also, consider contact with materials like aluminum alloys to prevent galvanic corrosion. Recommendation: High-performance zinc-nickel alloy plating or zinc-aluminum coatings (zinc flake coatings), which exhibit excellent corrosion resistance and compatibility with aluminum. Real Data: Zinc-nickel alloy plating typically achieves over 720 hours without red rust in salt spray tests.

Motor and Reducer Mounting Fasteners: Environmental Characteristics: May experience vibration and elevated temperatures. Some components may require controlled friction coefficients to ensure stable preload. Recommendation: Zinc flake coatings, which offer superior high-temperature resistance compared to traditional zinc plating, and have controllable friction coefficients. Phosphate and oil is an economical option but performs less effectively in high-temperature and corrosive environments. Real Data: Certain zinc flake coatings can withstand operating temperatures up to 150°C.

Suspension System Fasteners: Environmental Characteristics: Directly exposed to the external environment, susceptible to salt spray and mud/water corrosion. For high-strength bolts, hydrogen embrittlement risk is a significant concern. Recommendation: Zinc flake coatings or mechanical plating, both of which eliminate the risk of hydrogen embrittlement and provide excellent corrosion resistance. Real Data: Mechanical plating can achieve salt spray resistance of over 240 hours.

Braking System Fasteners: Environmental Characteristics: Safety-critical components with extremely high reliability requirements. May face high temperatures and certain corrosive environments. Recommendation: High-performance zinc flake coatings or zinc-nickel alloy plating. For components requiring specific friction coefficients, choose zinc flake coatings with integrated lubricants. Real Data: Fasteners in automotive braking systems typically require salt spray testing to exceed 720 hours.

Common Pitfalls to Avoid:

Focusing Solely on Cost: Low-cost electroplated zinc may fail quickly in harsh environments, leading to higher long-term maintenance costs and safety risks.

Ignoring Hydrogen Embrittlement Risk: For high-strength fasteners, always choose coatings with no hydrogen embrittlement risk or ensure thorough hydrogen embrittlement relief baking.

Neglecting Material Compatibility: Contact between dissimilar metals can cause galvanic corrosion; selecting appropriate coatings can mitigate this effect.

As critical C-parts in the automotive fastener supply chain, effective management of ball studs is essential for optimizing overall supply chain efficiency. We understand the challenges buyers and engineers face in ensuring stable supply, reducing costs, and improving quality. By partnering with us, you can:

Streamline Procurement: We offer one-stop solutions, reducing supplier numbers and management costs.

Optimize Inventory Management: We provide VMI (Vendor Managed Inventory) and JIT (Just-In-Time) delivery services, ensuring timely supply and reducing inventory buildup.

Enhance Quality Control: We have an IATF 16949 certified production system, ensuring product quality meets the highest standards.

Build Long-Term Partnerships: We are committed to establishing long-term, stable partnerships with our customers, jointly addressing supply chain challenges and achieving mutual benefits.

Meet a few members of our dedicated team, ready to help you:

Coco Chen, Director of Business Development: coco.chen@zjzrap.com

Freddie Xiao, Account Manager: freddie.xiao@zjzrap.com

Brian Xu, Technical Sales Assistant: brian.xu@zjzrap.com

Explore our capabilities and comprehensive product range: https://www.zjzrqc.com/product

IATF16949 Certified

HQ& Factory Address:

No. 680, Ya'ao Road, Daqiao Town, Nanhu District, Jiaxing City, Zhejiang Province, China

Online Map to see where we are exactly located:

Online Map to see where we are exactly located:

Linkedin Page • Products • Video Showcase • Contact Us • CAPAFAIR Ningbo 2025

And Get A Free Consultation!

English

English 中文简体

中文简体