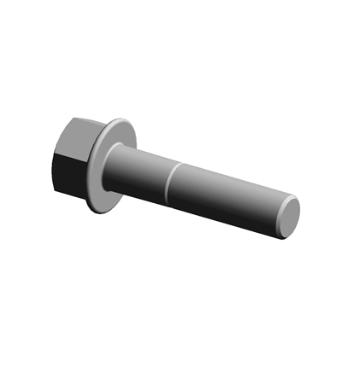

Understanding GB/T 16674.2 Hexagon Flange Bolts with Metric Fine Pitch Thread Equivalence, IATF16949, PPAP compliant supplier

Integrated Flange: Distributes clamping load over a larger area, reducing stress on joined materials and often eliminating the need for a separate washer.Metric Fine Pitch Thread: Offers increased resistance to loosening under vibration compared to coarse threads, and allows for finer torque adjustment, essential for controlling preload in sensitive automotive assemblies.Small Series: Refers to specific dimensional characteristics.

Understanding International Equivalences: GB/T 16674.2 vs. ISO and BS

ISO 15072:1999 (International): GB/T 16674.2 is consideredEquivalent to ISO 15072:1999. This means that the dimensional, mechanical, and functional characteristics of bolts manufactured to these two standards are designed to be interchangeable in most applications. This direct equivalence is a critical piece of information for global supply chain planning.BS 1083:1951 (British Standard): GB/T 16674.2 is listed as aReference to the older British Standard BS 1083:1951. A "Reference" designation typically indicates a historical link or similarity, but not direct interchangeability without careful verification of specific requirements, as dimensions or other properties may differ.

Sourcing Flexibility: Knowing that GB/T 16674.2 is equivalent to ISO 15072 allows automotive manufacturers and their suppliers to confidently source these critical fine pitch flange bolts from manufacturers adhering to either standard, broadening their supplier base, especially from major manufacturing hubs like China.Supply Chain Resilience: Diversifying sourcing options through recognized equivalent standards helps mitigate risks associated with single-source dependencies or regional supply disruptions.Cost Optimization: Accessing a wider pool of equivalent suppliers can lead to more competitive pricing without compromising technical specifications or quality.Seamless Integration: Bolts meeting either GB/T 16674.2 or ISO 15072 specifications are designed to function identically in assemblies requiring metric fine pitch, ensuring consistent performance in engine components, transmission assemblies, chassis systems, and other areas prone to vibration.

Technical Suitability for Automotive:

Vibration is a Factor: The fine thread pitch provides inherent self-locking properties, crucial for maintaining joint integrity in dynamic vehicle environments.Space is Limited: The integrated flange eliminates the need for a separate washer, reducing component count and assembly complexity in compact spaces.Precise Clamping is Required: Fine pitch threads allow for more accurate torque control, preventing over-tightening and ensuring optimal preload for sensitive components.

Meet a few members of our dedicated team, ready to help you:

Coco Chen, Director of Business Development: coco.chen@zjzrap.com

Freddie Xiao, Account Manager: freddie.xiao@zjzrap.com

Brian Xu, Technical Sales Assistant: brian.xu@zjzrap.com

Explore our capabilities and comprehensive product range: https://www.zjzrqc.com/product

IATF16949 Certified

HQ& Factory Address:

No. 680, Ya'ao Road, Daqiao Town, Nanhu District, Jiaxing City, Zhejiang Province, China

Online Map to see where we are exactly located:

Online Map to see where we are exactly located:

Linkedin Page • Products • Video Showcase • Contact Us • CAPAFAIR Ningbo 2025

And Get A Free Consultation!

English

English 中文简体

中文简体