Understanding Fatigue in Automotive Spring Washers and How Design Optimization Extends Lifespan

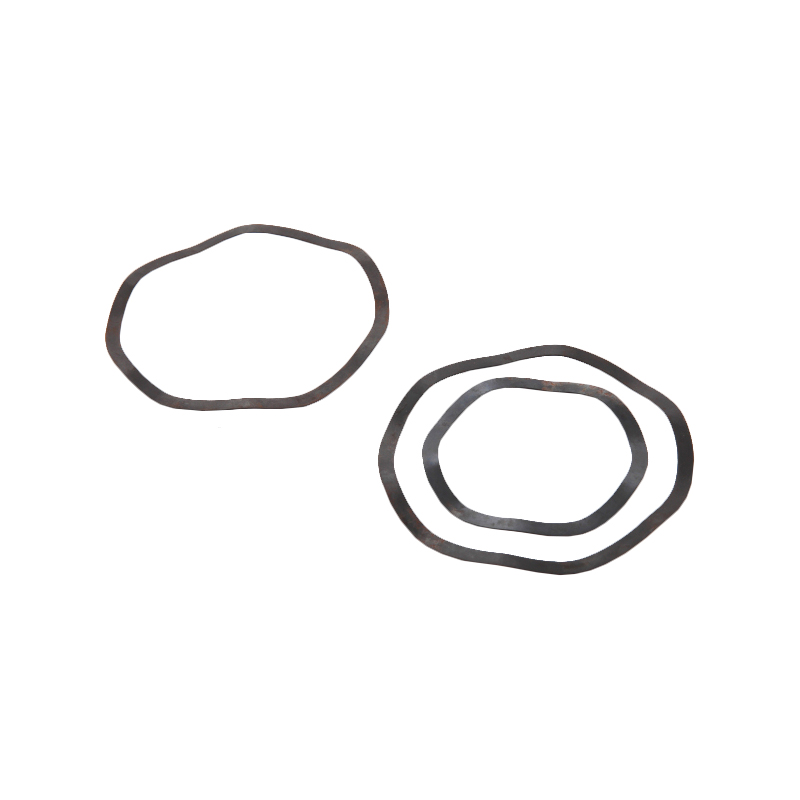

Automotive spring washers are critical components in high-vibration assemblies, helping to maintain consistent clamping force under dynamic conditions. But like any mechanical part exposed to stress and movement, they face the persistent challenge of fatigue. Fatigue failure doesn't happen overnight—it’s a gradual process that results from repeated cyclic loading, often leading to microscopic cracks that grow over time. For engineers and buyers in the automotive sector, understanding the causes of fatigue in spring washers is key to choosing or designing a solution that ensures safety, reliability, and long-term performance.

At the core of fatigue lies the washer's material structure and the nature of the forces it encounters. Spring washers operate by flexing slightly to absorb energy, which makes them highly effective in resisting loosening due to vibration. However, this constant flexing also subjects the washer to alternating stresses. Over time, especially under high-frequency loads such as those found in transmissions or engine mounts, the metal can develop internal cracks. These can be accelerated by factors such as sharp corners in the washer profile, surface imperfections, or inadequate surface treatments, which act as stress risers and compromise fatigue resistance.

Manufacturers like us invest heavily in testing methods to ensure our automotive spring washers can withstand the toughest conditions. Among the most widely used fatigue testing approaches are S-N (Stress vs. Number of Cycles) curves, which graphically represent the number of cycles a washer can endure at a given stress level before failing. These curves, derived through controlled lab testing, give a predictive insight into product lifespan. In modern settings, finite element analysis (FEA) is also commonly applied during the design phase. FEA allows engineers to simulate real-world stress scenarios and refine the washer’s geometry to distribute loads more evenly, reducing localized stress concentrations that could initiate fatigue cracks.

Design optimization is an essential strategy for enhancing fatigue life. This involves adjusting parameters such as washer thickness, coil angle, and contact surface design. Even small geometric modifications can dramatically influence how the washer deforms under load. For example, a broader contact surface can reduce pressure per square millimeter, while a well-calculated helical angle can improve the spring effect without over-straining the material. We often collaborate closely with automotive OEMs and Tier 1 suppliers to tailor washer designs to their specific applications, balancing performance with manufacturing feasibility.

Material selection plays a parallel role in fatigue prevention. While carbon steel is common for general applications, high-performance automotive spring washers may be made from alloy steels or stainless steel for improved resistance to both mechanical and environmental stressors. Surface treatments like shot peening can also induce beneficial compressive stresses on the surface, delaying the formation of fatigue cracks. These techniques, when applied correctly, extend operational life significantly and reduce maintenance or replacement costs down the line—a crucial advantage in high-volume automotive production.

Not every application requires an extreme fatigue-resistant washer, but for assemblies subject to thermal cycling or mechanical shock, cutting corners on washer quality can lead to costly consequences. That’s why experienced manufacturers prioritize both empirical testing and theoretical modeling to ensure that their washers perform under real-world conditions. We understand that what seems like a minor component can make a major difference in assembly integrity.

In choosing automotive spring washers, understanding fatigue behavior isn’t just a technical concern—it’s a strategic one. By selecting the right design, material, and treatment combination, you’re not just buying a washer; you’re investing in long-term performance and reliability. With decades of experience behind our product development, we’re proud to support our partners with solutions that go beyond standard expectations and keep your assemblies locked in, cycle after cycle.

And Get A Free Consultation!

English

English 中文简体

中文简体