Rockwell to Vickers Hardness: A Complete Guide

Understanding Rockwell Hardness

The Rockwell hardness test (developed in 1919) is based on the depth of indentation created by a steel or diamond cone (called a Brale indenter) or a hardened steel ball. It measures hardness directly on a dial, which makes it fast and widely used in industrial applications.

Scales: Different Rockwell scales (A, B, C, etc.) exist, depending on the indenter and load.

Rockwell C (HRC): One of the most popular scales, especially for hardened steels.

Rockwell B (HRB): Common for softer materials such as brass and copper alloys.

The advantage of Rockwell is speed and simplicity—no microscope is needed to measure indentation size.

Understanding Vickers Hardness

The Vickers hardness test (introduced in 1921 by Smith and Sandland at Vickers Ltd.) uses a diamond-shaped pyramid indenter. Unlike Rockwell, it measures the diagonal length of the indentation under a specific load and then applies a formula to calculate hardness.

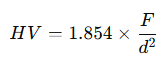

Formula:

where F is the applied force (kgf) and d is the average diagonal length (mm).

Key Advantage:

The Vickers test can be used for a wide range of materials, from very soft to extremely hard, and provides a single scale for all.

Why Convert Rockwell to Vickers?

Conversion becomes essential when:

Comparing data from suppliers using different testing standards.

Meeting international specifications (ASTM, ISO, DIN).

Quality control across industries that standardize on one scale.

Research that requires cross-verification of hardness results.

For example, a heat-treated steel component might have hardness given in HRC, while a material property database may list the same material’s hardness in HV.

Rockwell to Vickers Conversion Principles

It is important to note that no exact formula exists for conversion between Rockwell and Vickers, since both tests rely on different mechanics of deformation. Instead, standardized conversion tables (ASTM E140, ISO 18265) are used.

General Conversion Trends:

Higher HRC values correlate with higher HV values.

The relationship is nonlinear—meaning a jump of 5 HRC at lower hardness may not equal the same jump in HV at higher hardness.

Approximate ranges:

20 HRC ≈ 235 HV

40 HRC ≈ 392 HV

60 HRC ≈ 650 HV

These conversions are approximate and should only be used as a guideline.

Factors Affecting Accuracy

Several variables affect conversion reliability:

Material type – Steels, nonferrous alloys, and ceramics behave differently under indentation.

Heat treatment – Microstructure variations (martensite, bainite, ferrite, etc.) affect hardness response.

Test precision – Surface finish, indentation depth, and operator skill can influence results.

Standard compliance – Always reference recognized standards like ASTM E140 for conversions.

Best Practices for Converting Rockwell to Vickers

Use conversion tables from authoritative standards (ASTM, ISO) rather than unofficial charts.

Avoid cross-scale comparisons (e.g., HRB to HV) for materials beyond recommended ranges.

When accuracy is critical, perform a direct test rather than relying solely on conversion.

Document the scale (e.g., HRC vs. HRB) to avoid misinterpretation.

And Get A Free Consultation!

English

English 中文简体

中文简体