Choosing the Right Automotive Pin Fasteners for Your Vehicle's Performance and Safety | IATF16949, PPAP compliant

These small but mighty components are vital for connecting parts that experience both static and relative motion, such as in hinge mechanisms. But selecting the right automotive pin fasteners is a task that requires careful consideration, as these fasteners must withstand the stresses and forces they encounter throughout the lifespan of a vehicle. From the materials used to their specific applications, every detail counts when choosing pins that will help secure components while maintaining safety and efficiency.

The first factor to consider when selecting automotive pin fasteners is the material. Automotive pins are available in a variety of materials, each suited for specific applications based on their unique properties. Steel, stainless steel, and aluminum are some of the most commonly used materials, and each has its advantages. Steel is known for its durability and strength, making it ideal for high-stress applications. Stainless steel offers excellent corrosion resistance, which is crucial for parts exposed to harsh environmental conditions. Aluminum, on the other hand, is lightweight, which is particularly beneficial for applications where weight reduction is important. Understanding the specific requirements of your vehicle’s design will guide you in selecting the most appropriate material for the pin fasteners.

In addition to material choice, it's important to consider the size and tolerance of the pins. Pin fasteners need to fit securely within the components they connect, and even a slight deviation in size or tolerance can compromise the integrity of the joint. Automotive fasteners, such as pin screws, need to match the diameter, length, and strength required for each specific application. Over- or under-sizing pins can result in improper connections, leading to premature wear and potential failure of the connected components. This is especially crucial when these pins are used in critical components, such as suspension systems, steering links, and door hinges.

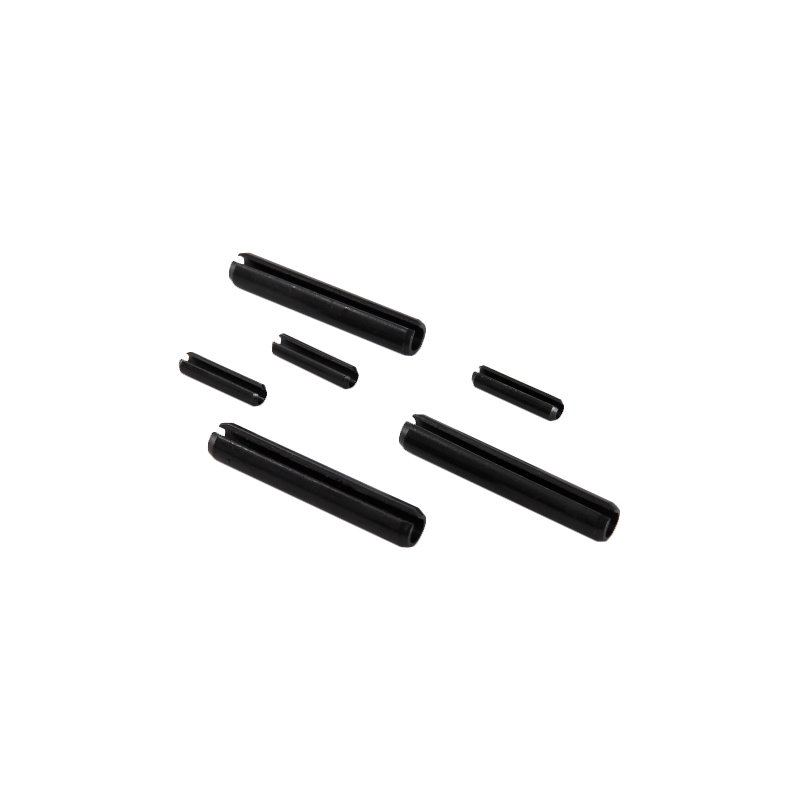

Another key aspect to evaluate is the specific type of automotive pin fastener required for the job. Automotive pins come in a variety of designs, including clevis pins, cotter pins, and shoulder pins. Each type has its own purpose, with some designed to allow for more movement or pivoting while others are used for securing components that require a fixed position. For example, clevis pins are often used in suspension components, while cotter pins are commonly employed for securing wheels and axles. The type of pin fastener you choose should directly correspond to the type of motion or connection required in the application.

Environmental factors play a significant role in the longevity and performance of automotive pin fasteners. For instance, factors such as temperature extremes, exposure to moisture, and chemical exposure can all affect the performance of the pins. In regions where vehicles are subjected to high humidity or salty air, such as coastal areas, corrosion resistance becomes a critical consideration. Automotive screw washers, often used in conjunction with pins, can provide additional protection against corrosion by creating a barrier between the pin and the environment. The combination of high-quality automotive pin fasteners and appropriate washers ensures that your connections remain secure, even under the harshest conditions.

Another consideration is the cost-effectiveness of the automotive pin fasteners. While it might be tempting to opt for the least expensive option, it is important to balance cost with quality. Cheap, low-quality pins may lead to frequent replacements and maintenance costs down the line, undermining the overall value of your investment. High-quality automotive pins may carry a higher upfront cost, but their durability and performance will save you money in the long run by reducing the need for repairs and replacements. Choosing pins with the right balance of cost and performance is key to maximizing the longevity and safety of your vehicle.

Finally, the role of automotive pin fasteners in ensuring the safety and performance of vehicles cannot be underestimated. A properly selected and installed pin plays an essential role in maintaining the integrity of mechanical assemblies, particularly in moving parts like hinges, suspension links, and steering mechanisms. Whether it’s for stationary or moving connections, these pins ensure that your vehicle remains in optimal working condition. By selecting automotive pin fasteners based on material, size, type, and environmental factors, you ensure that the components in your vehicle are securely connected, reducing the likelihood of failure and enhancing overall vehicle reliability.

Meet a few members of our dedicated team, ready to help you:

Coco Chen, Director of Business Development: coco.chen@zjzrap.com

Freddie Xiao, Account Manager: freddie.xiao@zjzrap.com

Brian Xu, Technical Sales Assistant: brian.xu@zjzrap.com

Explore our capabilities and comprehensive product range: https://www.zjzrqc.com/product/

IATF16949 Certified

HQ& Factory Address:

No. 680, Ya'ao Road, Daqiao Town, Nanhu District, Jiaxing City, Zhejiang Province, China

Online Map to see where we are exactly located:

Online Map to see where we are exactly located:

Linkedin Page • Products • Video Showcase • Contact Us • CAPAFAIR Ningbo 2025

And Get A Free Consultation!

English

English 中文简体

中文简体